Image Enable Your Supply Chain, Blockchain Enable Your Images

Blockchain has great potential to solve problems and address supply chain problems. Personally, the area that excites me most is track and trace—especially when you consider the possibility of taking these capabilities to the next level.

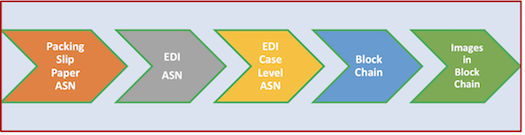

Let us take a step back and look at the current supply chain processes and their evolution.

Packing slip, paper ASN

Advance Shipment Notices (ASNs) are sent in advance to let the receiver know what products or deliveries are hitting the facility. This allows the receiver to do a few things better including:

- Preparing labor to receive the product.

- Plan for order allocation and fulfilment.

- Effectively plan the supply and demand to run the corporate supply chain optimally and efficiently without huge spikes.

- Raise awareness in advance of potential exceptions.

In the past, supply chain partners shared packing slips via fax. Information sharing in this manner, although labor intensive, was worth it because it resulted in collective benefit. It was a step in the right direction. However, the human element and the vagaries of fax technology made it a slow and error prone process.

This first step provided a concrete example of the benefits of sharing information. In many cases, it created a new mindset. Even though many partners were competitors, collaboration provided a win/win.

EDI – ASN

Electronic Data Interchange (EDI) allows partners in the supply chain community to share information through an established communication infrastructure. Early on, before the internet, organizations needed to invest in T1 lines or modems to establish this connectivity. Today, it is a seamless and easy process over the Internet.

Along with EDI came EDI standards that hoped to streamline and create standards for consistent types of information. For the system to work, all the different partners need to interpret the data in the same way and send and receive the same data in a shared and understood format. One of the most frequently used transactions was the 856 (a shipment status message) that was sent every time a shipment arrived at a different point in the shipping process. It provided visibility across the supply chain about shipment status.

EDI: Case-level ASN

As EDI became the norm, visibility improved great. Case-level ASNs appeared. When partners worked well together and achieved great performance metrics, thereby creating a trusted relationship. In these instances, they sometimes chose to forgo verifying the content of every box (based on the track record of excellence and accuracy). That offered huge labor savings at the docs. In addition, vendors were their own manufacturing plants and received case levels in advance. This allowed the products to be received in distribution centers without extra handling.

Blockchain

Now, while all these processes are being executed impeccably, where does blockchain come in? All the hype around the technology tells you that it must solve a problem. One of the fundamental concepts of blockchain is that information is shared within a group of pre-authorized trusted parties and this information is stored in computers all over the world (in the cloud). This strategy allows third parties (called validators or rating agencies) to be added as needed. Information is monitored and available to all involved in the transaction. If, for example, a group of components were found to be defective or counterfeit, that information would be available to everyone involved in the transaction.

The second use case where this will be very helpful is track and trace. Let’s take an example from the food industry. A food manufacturer makes potato salad and uses tomatoes that came from Chile or Guatemala. That farmer can be added as a partner and can send transactions so that the origins of the tomatoes can be tracked and traced back to the originating farm. That’s equally true of any type of component or ingredient. Any issues that rise can be handled proactively even if the problem occurs mid-shipment. (Consider high-heat conditions, for example.) The technology allows the problem to be pinpointed to exactly where it occurred.

Images in the supply chain, images in blockchain

Now, let’s consider how this technology can be extended for further benefit. We all know images provide extra value, facilitate easier and quicker communication, and allow for easy illustration. In supply chain, problems are very quickly and easily understood when explained with pictures. Images also are an effective tool in resolving insurance claim.

Adding images to supply chain entities help in a big way because they become available with any supply chain transaction. Consider the 856 status reports: In addition to having the seal number from the container, you could add a picture of the seal for added credibility. It also allows 3PL operators to demonstrate and prove that they did their job right.

Adding those images to the blockchain makes them available for the entire partner community, including the third-party validators and the rating agencies. Visibility across the entire chain is a gold standard in the supply chain.

Of course, we can’t really talk about blockchain without at least mentioning cryptocurrency. Today, it doesn’t really have a place in the equation. To be truly useful, we must get to the point that it is regulated and accredited by majority industry players. Standards would allow all parties accountable. Unfortunately, we simply aren’t there yet.

Let us know your thoughts in the comments section below. Have you implemented blockchain in your supply chain? What benefits and challenges have you seen?

Recommended Posts

Top 10 Best Practices that You Can Implement in Your Distribution Center Tomorrow with No System Changes and Very Little Process Changes

December 15, 2021